Maintenance

Aries is able to perform aeronautic MRO (maintenance, repair & overhaul) in jigs and tools used to manufacture and transport aircrafts. Maintenance in the aeronautical sector is a major pillar that allows companies to ensure that their facilities and equipment remain in perfect conditions throughout their operational life, guaranteeing quality airplanes and products.

Aries employs highly qualified personnel capable of carrying out the different tasks required in each of them. Operators have the experience and resources necessary to perform the different works required, always achieving the maximum satisfaction of our clients. Some of the daily maintenance tasks performed by Aries employees are:

- Advanced technical welding, metal sheet forming, boilermaking and surface treatments.

- Watertight and vacuum tests.

- Measurements services.

- Technical and engineering services.

- Electric, combustion and automotive engines assembly and maintenance; and with knowledge to solve common and specific malfunctions in them.

- Low voltaje electrical installations and repairs.

- PLCs and controllers installation and programing.

- Electronical repairs.

- Hydraulic and pneumatic systems.

Aeronautic maintenance can be divided into 5 types, these are:

- Predictive maintenance: data collection and further analysis plus users experience allow Aries operators to predict the failure modes of the equipment or installations analysed in orther to avoid any operational stoppages.

- Preventive maintenance: to preserve equipment, installations and tolling systems by inspecting, cleaning and readjusting them before they experience any damage to ensure their proper operation and reliability.

- Conductive maintenance: combines preventive and predictive maintenance, including certain basic tasks and/or inspections, where it is possible to check the proper functioning of the installation. In case any malfunction is detected Aries will perform all the readjustments necessary to guarantee the successful return to operation.

- Corrective maintenance: it corrects the detected defects in installations or equipment. It is of vital importance the celerity of the repair so the as the breakage means production must be stopped.

- Normative–legal maintenance: preventive maintenance containing a set of actions necessary to comply with the specifications established by Regulations or Standards.

References

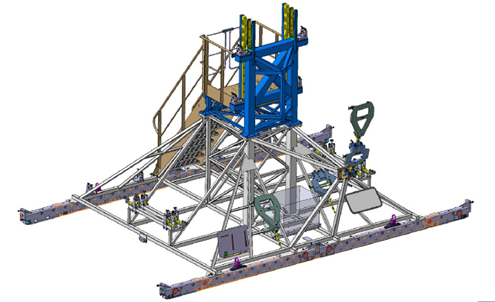

1. Maintenance at Airbus facilities

- Preventive, conductive and corrective maintenance of the port / Harbour ramp.

- A380 Transport jigs maintenance: HTP, CBF & containers.

- Transport vehicle maintenance: MPV (multi-axle vehicle with electro-hydraulic drive).

- Maintenance of two trailers each one installed with a three-phase 30KVA portable generator.

2. Maintenance of the INVAR curing toold in AIRBUS ILLESCAS and in EMBRAER Portugal

- Surface damage repairs in the curing area of the tool.

- Vacuum pipe repair of curing tools.

- Turning tools intallation using Laser Tracker.

- Installation of cutting tools using Laser Tracker to level and fix in place.

3. Maintenance and Refurbishment of the Beluga Transport Jigs (Update from ST to XL)

- Visual and penetrant liquids welds inspections.

- Several repairs: crashes, damaged parts, new commercial elements…

- Tightening torques and different fixing elements.

- Spring Boxes tests.

- Weight and Balance and Laser Tracker measurements.

To guarantee complete traceability of transport jigs maintenance operations, Aries has developed a system that check the arrival and departure conditions of the equipment (Arrival and departure check-Lists), including detailed reports of the maintenance performed (preventive, mechanics, electro-preventive, corrective, conductive….) and spare parts management.